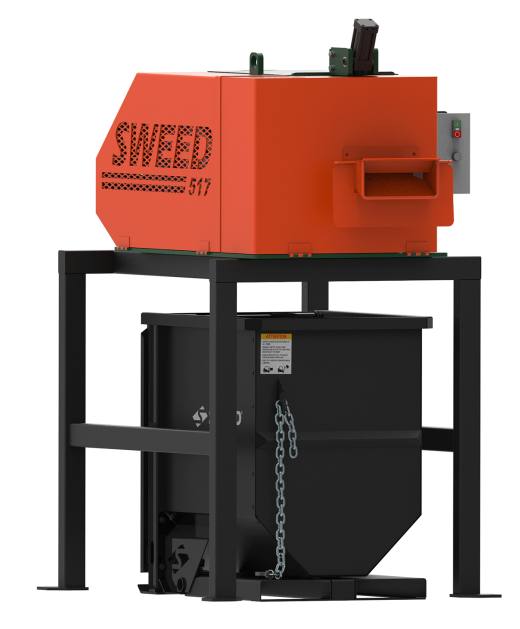

Model CE 517 XHD is a heavy duty model intended for companies that process large volumes of strip iron with a maximum width of 5 cm or that process significant amounts of linear materials. In order to withstand aggressive environments, this model has been equipped with a 12 mm sheet steel housing.

Model CE 517 XHD also has an equipment specifically designed for customers who need to process steel wire (e.g. wire from bales packaging). This machine can also handle piano wire effortlessly.

The machine is equipped with a magnetic starter to protect the users from unexpected restarting after a power loss. The feed mechanism, which is connected to a foot switch, is activated by compressed air. This is to ensure the safety of the operator.

Capacities

-Tire iron 12.5 mm x 3 mm

-Tape iron 19 mm x 3 mm

-Tire iron 8 mm x 3 mm

- Tire iron 25.4 mm x 3 mm

-Tyre iron 32 mm x 1.6 mm

- Tire iron of 38 mm x 2.0 mm

-High tensile strength binding wire (for bales)

- Solid aluminum and copper rods

Technics about the machine

(= standard for Europe)

Feed speed: 27 m/min

Length of cut material: +/- 90 mm

Input - opening: 168 x 41 mm

1 fixed knife + 1 rotating knife which is locked between 2 solid flywheels for extra cutting power.

In conformity with CE standards.

Comes with a user manual in Dutch.

Health and safety

An emergency stop stops the machine as soon as you press it. At that moment, the compressed air cylinder immediately opens.

The level of noise production is very difficult to determine and is also very dependent on the conditions of use. If you process steel or cap, the noise production will be different. The type of collection bin is also an important factor in sound production.

Depending on the material you chop, the machine can produce dust.

Maintenance

The steel blades of this chopper can be turned 4 times before they need to be replaced.

The manual with color pictures shows you step by step how to rotate or change a knife. It is difficult to determine how long a knife can last. This varies from customer to customer. Most of our customers rotate knives once a year. Customers with large piles of rusty tires or customers who cut very thin material will have to change their knives faster.

Regular lubrication and cleaning are recommended.

Environment

Option #1: customers with steel straps:

You no longer have to drive around with trucks that transport more air than material.

Option #2: customers with PET straps:

Making new material from recycled straps saves up to 75% in CO2 energy costs. With every kg of PET gained, you save 4.3 kg of CO2. This equates to 40 km of driving.